-

20+ Years

Professional SolutionsServing over 1000 companies in China,over 100 overseas companies. -

65 Patents

lnnovationIntegrate innovative ideas into every detail,Intimate and practical products,extraordinary experience. -

3 Years

WarrantyISO9001:2015 Quality system,One-stop solution for all After-sales service available in mostcountries.

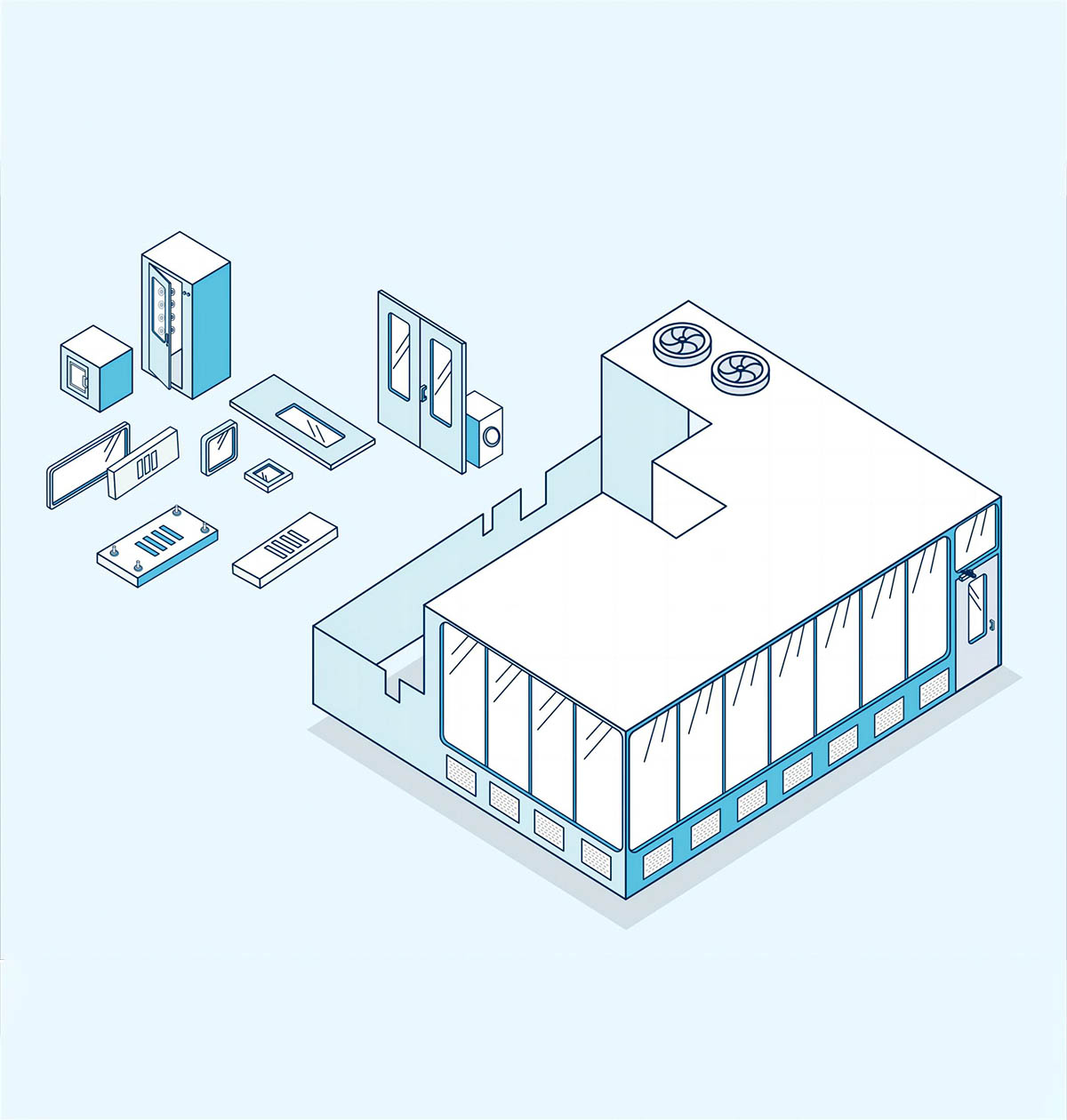

Modular Cleanroom Solutions

Dersion delivers fast, flexible, and scalable modular cleanrooms designed for modern manufacturing. Our pre-engineered system enables quick installation, easy expansion, and up to 98% material reusability, ensuring long-term value and reduced downtime. Supported by CE, ISO, and UL certifications, we provide customized layouts, HVAC integration, and intelligent control to meet strict cleanliness and process requirements across all industries.

LEARNMORE+

One-Stop Cleanroom Service

Dersion offers a complete end-to-end cleanroom solution, covering every stage from concept to delivery. Our team provides free design planning, precision manufacturing, HVAC integration, on-site installation, and long-term technical support—ensuring a seamless experience and consistent project quality. With a 20,000 m² smart factory, advanced production equipment, and CE/ISO/UL certifications, we deliver reliable, cost-efficient cleanrooms tailored to each customer’s industry and process needs.

LEARNMORE+

Industry-Focused Cleanroom Expertise

Dersion provides tailored cleanroom solutions engineered to meet the unique standards of each industry. Whether for pharmaceutical production, biotechnology research, medical device manufacturing, semiconductor fabrication, electronics assembly, or food and cosmetic processing, our systems ensure precise contamination control, stable environmental performance, and global regulatory compliance. With modular design flexibility, integrated HVAC engineering, and intelligent monitoring, Dersion delivers reliable, efficient, and scalable cleanroom environments that support high-purity processes and accelerate our clients’ path to quality and innovation.

LEARNMORE+

hot products

welcome to us

WE OFFER THE HIGH QUALITY PRODUCTS

With the mission of “becoming the preferred supplier of small and medium-sized cleanrooms”, Dersion continues to promote the upgrading and application of modular cleanroom technology, helping global customers achieve the goal of efficient and low-carbon sustainable development.

-

Food Industry Cleanroom Solutions | Modular GMP & FDA Compliant Systems

Food Cleanroom Requirements: Cleanliness, Temperature Control, and Cost Challenges Explained As food safety regulations become increasingly strict, more food manufacturers are adopting cleanroom environments to control contamination risks and ensure stable production quality. Unlike pharmaceutica...

-

Optical Lens Coating Cleanroom Cost | Key Factors & Design Considerations

Factors Affecting the Cost of an Optical Lens Coating Cleanroom Optical lens coating is a precision process in which one or multiple layers of metallic or dielectric thin films are deposited onto optical components. These coatings are designed to modify optical properties such as reflection, tran...