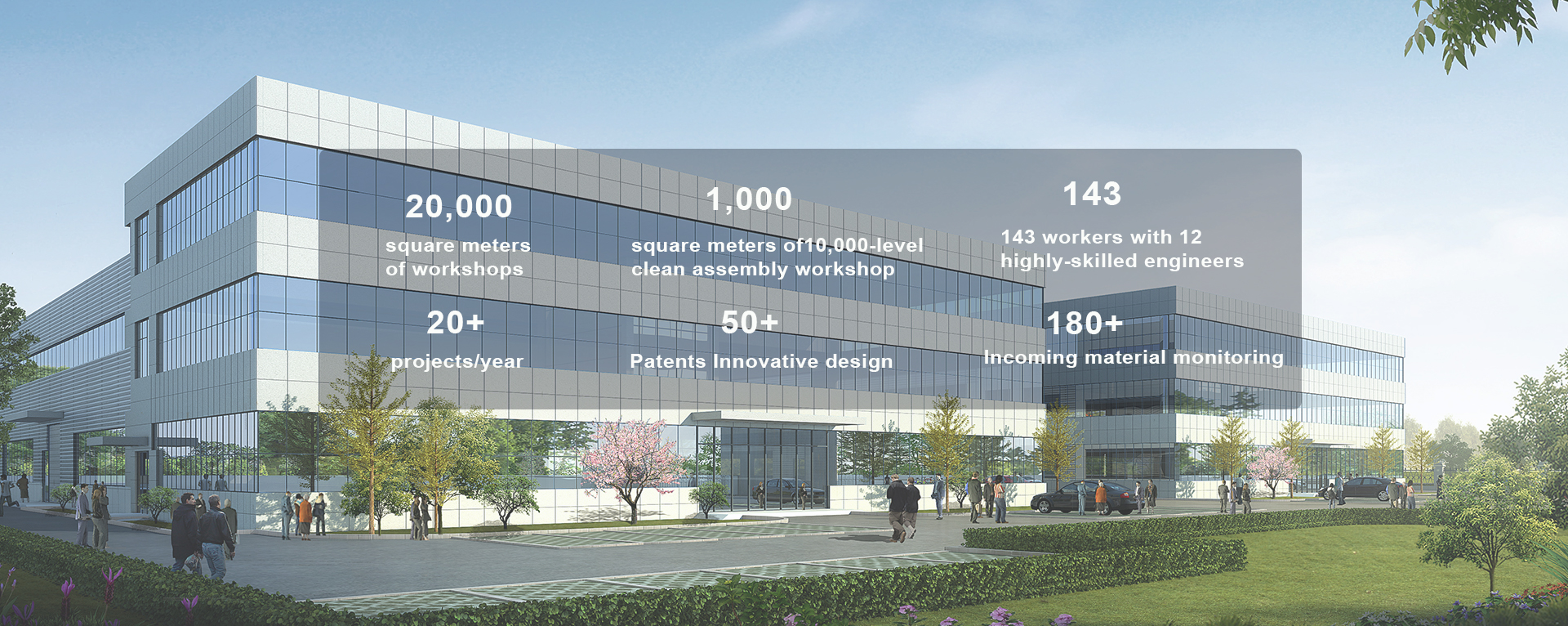

Founded in 2005, Dersion is a pioneer and leader in China's modular cleanroom field, committed to providing efficient and intelligent clean environment solutions for high-tech industries. The company has a 20,000 square meter intelligent production base and a 1,000 square meter 10,000-level modular cleanroom assembly workshop, equipped with the world's top "Yawei" laser equipment (including automatic material storage) and Germany's "Trump" sheet metal production line, to achieve 24-hour intelligent precision manufacturing, ensuring the high quality and delivery efficiency of products.

With more than 50 national invention patents for modular structures, SGS-certified ISO quality management system and SAP ERP digital management system, Dersion has built a full-chain core competitiveness from R&D design, production and manufacturing to installation services. The company has a professional design and engineering team, successfully serving nearly 60 Fortune 500 companies, covering high-end fields such as semiconductors, biomedicine, and new energy, and has become an industry benchmark with innovative technology and reliable delivery.

With the mission of "becoming the preferred supplier of small and medium-sized cleanrooms", Dersion continues to promote the upgrading and application of modular cleanroom technology, helping global customers achieve the goal of efficient and low-carbon sustainable development.

Factory standardized production

Improved quality control: standardized processes in a controlled environment ensure higher consistency and reliability.

Faster construction: on-site work is limited to assembly and connections, shortening project schedules and reducing contamination risk.

Lower costs: mass production reduces unit manufacturing costs and minimizes on-site labor and rework.

Reduced construction risk: welding, testing, and commissioning are completed in the factory, lowering on-site safety and uncertainty.

Easier acceptance and commissioning: modules are function-tested before delivery, requiring minimal on-site tuning and faster handover.

Traceability and standardization: complete production and inspection records facilitate quality traceability and regulatory compliance.

Flexibility and scalability: modular design supports phased expansion, replacement, or upgrades to adapt to future needs.

Simplified maintenance: standardized, replaceable components make routine maintenance, spare‑parts management, and remote diagnostics easier.

We provide 2D and 3D design solutions and tailor layouts to customer needs:

2D design deliverables:

Floor plans (scale drawings) showing room layouts, equipment locations, airflow paths, utility routes, and access/egress.

Elevations and sections for wall/ceiling finishes, filter/duct penetrations, equipment mounting heights.

P&ID / HVAC schematics indicating AHUs, fans, filters, dampers, sensors, and control interfaces.

Electrical and plumbing schematics, and zone zoning plans (pressure/cleanliness classifications).

DXF/PDF files for contractor use and site coordination.

3D design deliverables:

Full 3D models of rooms, modules, HVAC equipment, ductwork, piping, and service runs.

Clash detection and spatial coordination with structural and MEP elements.

Renderings and walkthroughs for visualization and stakeholder review.

BIM-compatible models (Revit/IFC) for downstream construction, prefabrication, and facility management.

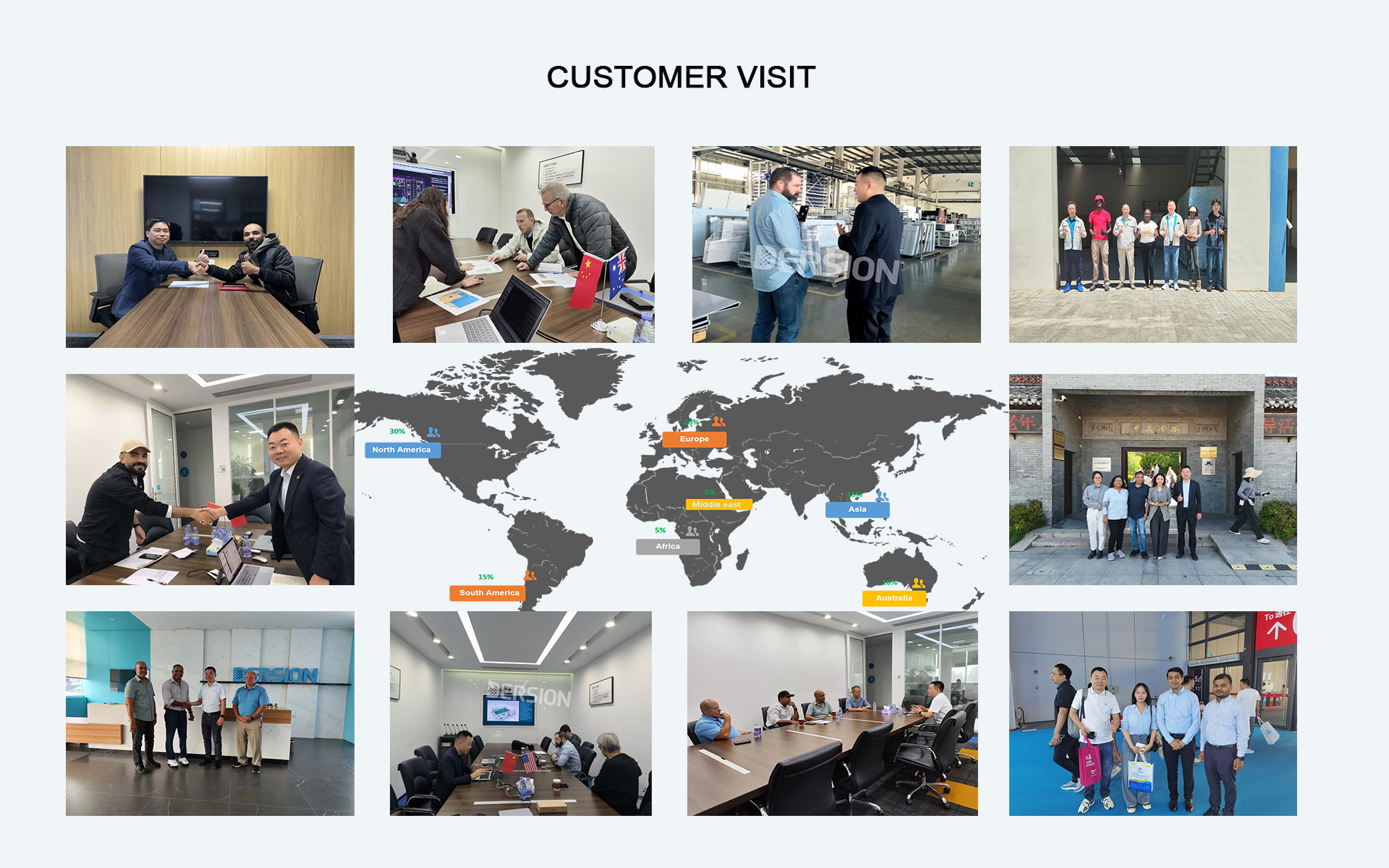

Our customers are distributed in more than 50 countries and regions, including the United States, Germany, the United Kingdom, Japan, Canada, Sweden, Switzerland, Spain, Denmark, Australia, New Zealand, South Africa, Thailand, Taiwan, Hongkong, Chinese Mainland etc.

After-sales service

1.Three-year after-sales guarantee

2.3 years of free warranty

3.Standardized product specifications and production processes

Value-added services

1.Provide equipment operation and maintenance briefing and training

2.Free clean room professional testing of imported instrument