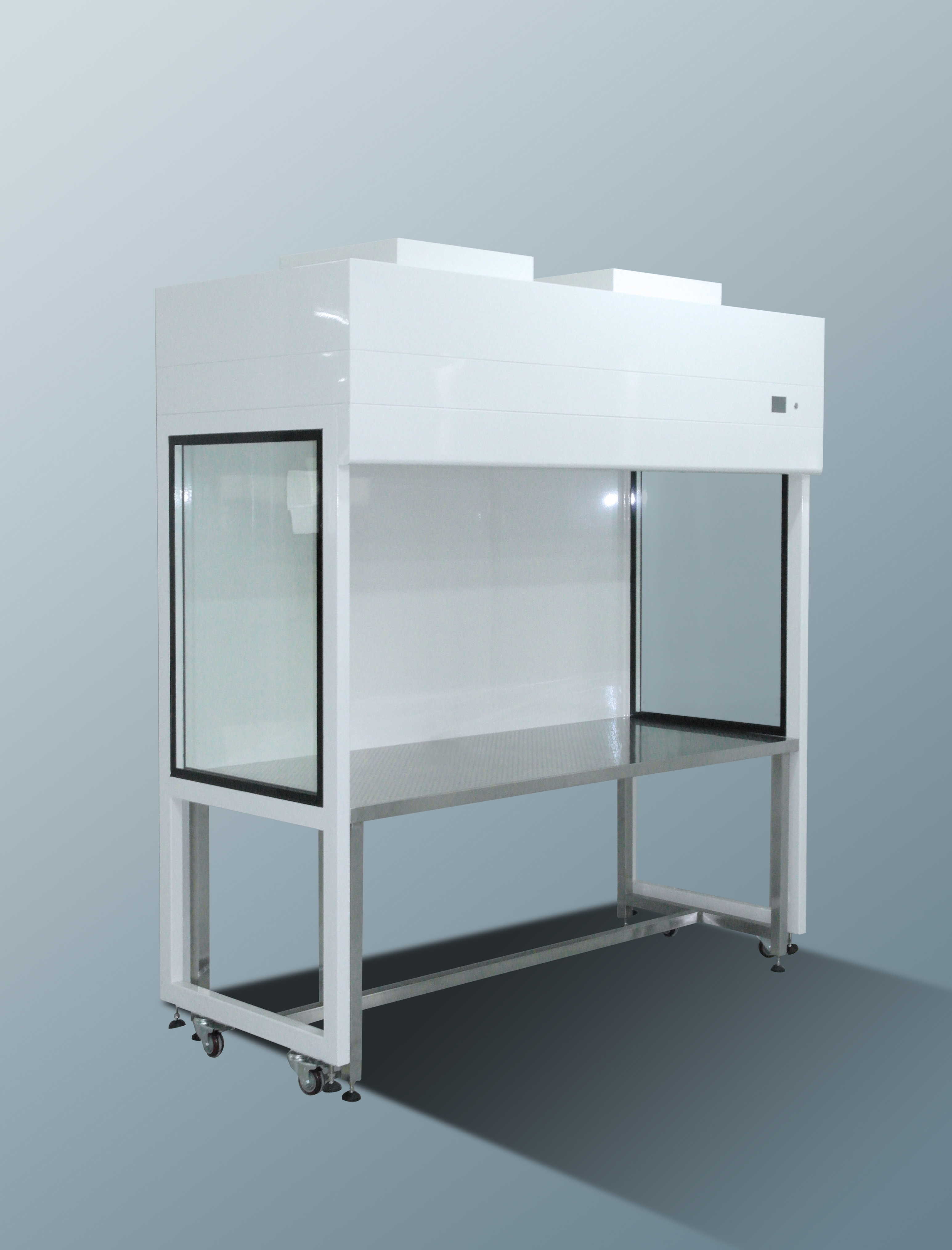

The ultra-clean workbench is an important environmental control equipment that has gained significant importance in various fields such as laboratories, hospitals, and electronic factories. Its sophisticated system integration allows for precise control of air purification, temperature, and humidity, providing a clean and stable working environment for experiments and production. In this article, we will discuss the advantages and development of ultra-clean workbench system integration.

First and foremost, the ultra-clean workbench is equipped with advanced air purification functions. The primary objective of this equipment is to filter out particles and harmful substances present in the air. It achieves this by utilizing high-efficiency filters and efficient air duct systems, thereby ensuring highly clean indoor air. The system integration of these purification mechanisms ensures that the workbench provides an uncontaminated environment, eliminating any potential risks associated with airborne contaminants.

The advanced air purification system in the ultra-clean workbench offers several advantages. One vital advantage is the elimination of contaminants that may interfere with experiments and production processes. This is particularly crucial in laboratory settings, where precision and accuracy are of utmost importance. By effectively removing particles and harmful substances, the workbench safeguards the integrity of experiments and ensures consistent and reliable results.

Additionally, the ultra-clean workbench contributes to the safety and well-being of individuals working in these environments. In hospitals, for example, where patients’ health is at stake, it is essential to eliminate any potential pathogens or allergens that could compromise patient safety. The integration of an efficient air purification system in the workbench aids in creating a controlled, sterile environment, reducing the risk of infections and cross-contamination.

Moreover, the ultra-clean workbench system integration extends beyond air purification. It also focuses on the precise control of temperature and humidity levels within the workspace. Certain experiments and production processes require specific environmental conditions to yield optimal results. By integrating temperature and humidity control mechanisms, the workbench ensures that these conditions are maintained consistently, allowing for reproducible experiments and high-quality production.

The development of ultra-clean workbench system integration has witnessed significant advancements in recent years. Technological innovations have enhanced the overall performance and capabilities of these workbenches. For instance, the integration of smart sensors allows for real-time monitoring of air quality, temperature, and humidity levels. This data can be analyzed to identify any deviations and enable prompt adjustments, ensuring a continuously clean and controlled environment.

Moreover, the integration of internet of things (IoT) capabilities has revolutionized the way ultra-clean workbenches can be remotely managed. With IoT integration, users can monitor and control the workbench parameters from anywhere at any time, using their smartphones or other connected devices. This enhances convenience, flexibility, and efficiency in laboratory and production settings, making it easier to maintain the desired environmental conditions.

In conclusion, the advantages and development of ultra-clean workbench system integration are crucial in providing a clean and stable working environment for experiments and production. The advanced air purification functions effectively remove contaminants and harmful substances, safeguarding the integrity of experiments and ensuring safety. The integration of temperature and humidity control mechanisms contributes to optimized results. Furthermore, ongoing technological advancements continue to enhance the performance and capabilities of ultra-clean workbenches, making them even more efficient and user-friendly. As industries increasingly recognize the importance of maintaining clean and controlled workspaces, the demand for ultra-clean workbench system integration will continue to grow.

Post time: Oct-24-2023